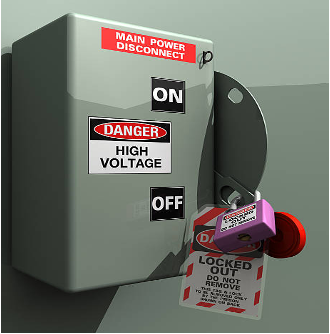

The control of hazardous energy, commonly referred to as Lockout Tagout, refers to the set of practices and procedures that, when applied correctly, safeguard employees from the inadvertent or accidental release of hazardous energy, primarily during the servicing, maintenance, or repair of equipment or machinery.

A release of hazardous energy can cause serious or fatal harm to employees performing work on or near the equipment where the energy release occurs. Hazardous energy can present itself in many forms, including mechanical, hydraulic, pneumatic, electrical, chemical, and thermal energy.

The UMBC Lockout Tagout Program must be followed when working on or around machinery or equipment that has been locked/tagged out, or when performing the act of applying or removing a lockout tagout device to perform services or repairs.

General Lockout Tagout Requirements:

- Only trained and authorized employees are permitted to apply a lockout/tagout device.

- Authorized employees may only remove a lockout/tagout device that they installed themselves.

- All affected employees shall be notified prior to application and removal of any lockout/tagout device.

- Never attempt to operate a machine or piece of equipment that has been locked out, for any reason.

- Follow all applicable machine/equipment-specific lockout tagout procedures.

For more information on the Lockout Tagout Program, please review the Program by clicking here.