A Biological Safety Cabinet (BSC) is a specific engineering control used in the biological laboratory to prevent exposure to or the contamination of biohazardous agents. BSCs should be used whenever there is a risk of splash or aerosol formation of biohazardous or potentially biohazardous materials. BSCs work by manipulating air flow surrounding the area where work is being done such that the majority of biohazardous aerosols generated inside the BSC remain in containment while the majority extraneous laboratory aerosols remain outside of containment.

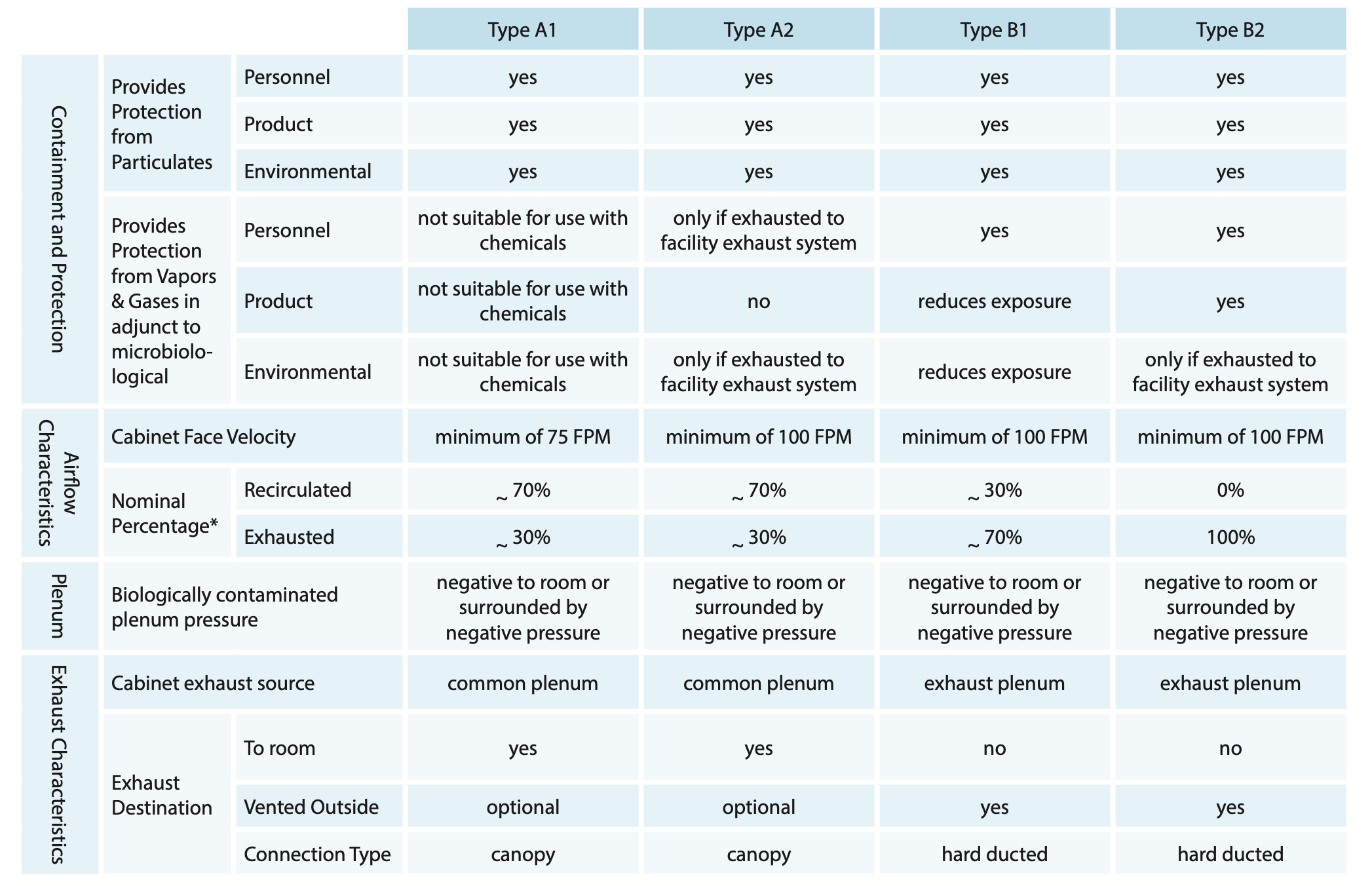

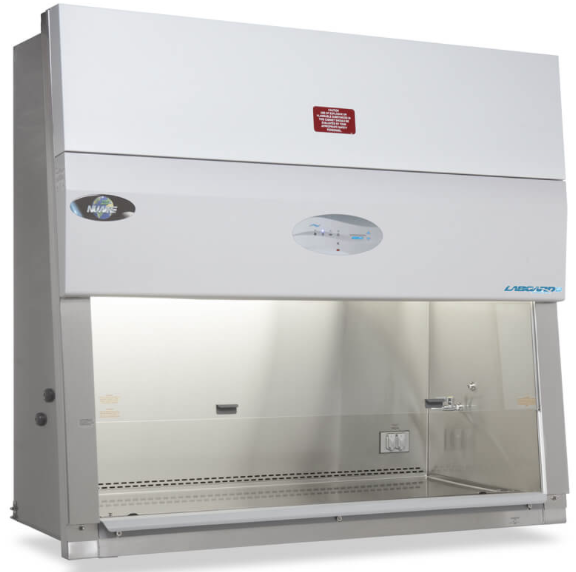

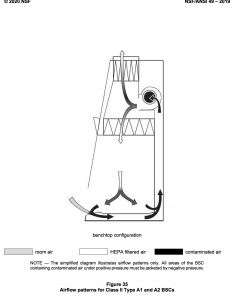

BSCs are divided into three classes (I, II, III) with class II being subdivided into five types (A1, A2, B1, B2, C1). The type of cabinet to be used will depend on the Biosafety Level of the microorganism as specified by CDC-NIH guidelines. For Biosafety Level 1 (BSL-1) microorganisms, standard microbiological practices will provide adequate protection. However, if additional protection is desired, any class of cabinet may be used by personnel working with these microorganisms. Class I and II Biosafety Cabinets will be used for low to moderate hazard microorganisms of Biosafety Levels 2 and 3. The main difference between the two is that Class II cabinets provide protection to personnel and the microorganism and Class I cabinets only provide protection to personnel. The most commonly used BSC is the Class II Type A1 or A2 cabinet, a figure of which can be found below.

Class III Biosafety Cabinets (also known as Glove Boxes) are required when working with high hazard microorganisms at Biosafety Level 4 (BSL-4). These cabinets are totally enclosed to provide the highest possible protection to personnel and the microorganisms. It is also important to note that glove boxes are also required for experiments using radioactive solids that may become airborne or with other highly toxic chemicals. Regardless of the type of research being conducted, it is important to follow safe practices and guidelines in order to minimize possible exposure.

More information on biosafety cabinets can be found utilizing the following resources